Cantilever racks are the unsung heroes of warehouse storage. While most people are familiar with the standard pallet racks, cantilever racks are a game-changer when it comes to storing long, heavy, or oddly shaped items. In this guide, we’ll walk you through everything you need to know about cantilever racks, from what they are to why they're essential for warehouse optimization.

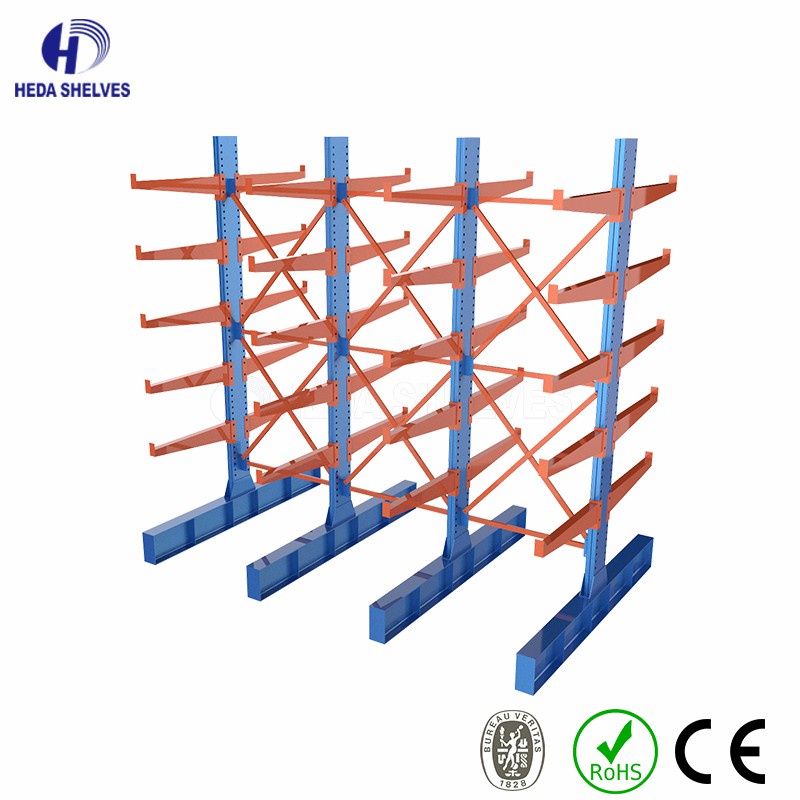

A cantilever rack is a type of storage system that features arms protruding from a vertical column. Unlike traditional shelving, which has horizontal shelves, cantilever racks are ideal for storing items that don’t fit well on typical shelving, such as lumber, pipes, or large furniture.

Key Components:

Vertical Columns: The backbone of the rack, providing stability.

Horizontal Arms: The extended arms that hold the items. These can be customized in length and height.

Base or Footplate: Secures the structure to the ground.

Cantilever racks are available in various configurations and sizes, making them versatile for different storage needs.

Cantilever racks work by utilizing its arm extensions to hold products, allowing for better space utilization. The open design enables easy access to items from either side of the rack, while the arms support the weight of long or oversized materials. This design maximizes the use of vertical space, making it ideal for warehouses with limited floor space.

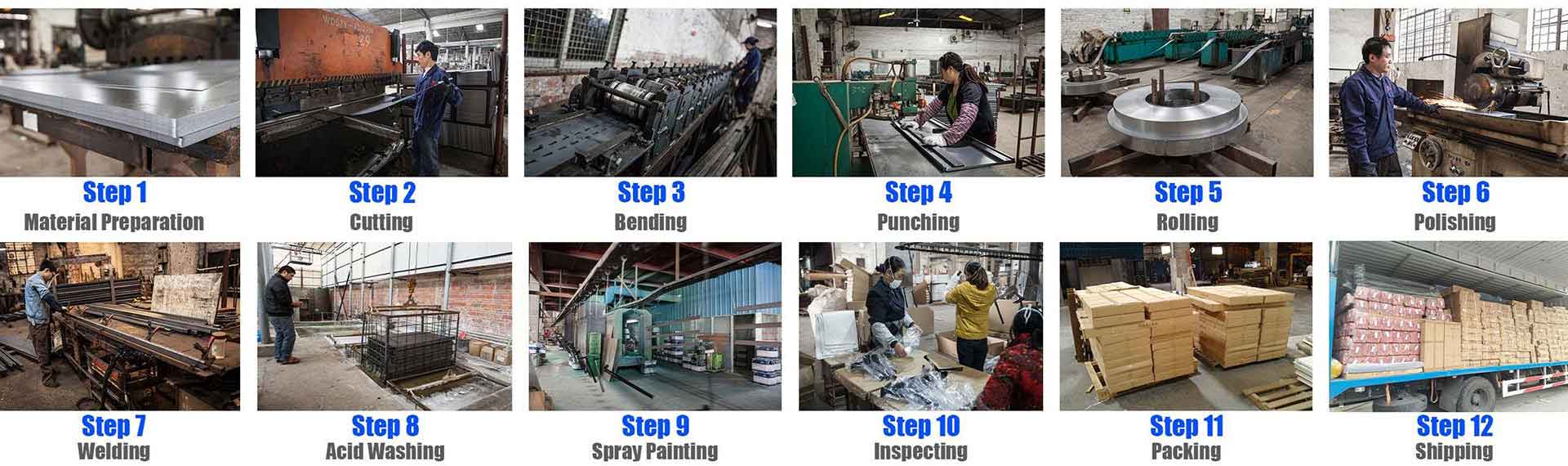

The first step in manufacturing a cantilever rack is sourcing high-quality raw materials-Q235 Cold roller steel. High quality Steel material for strength, and load-bearing capabilities. Steel sheets, bars, and columns are used as the primary components for the rack’s frame and arms.

Once the materials are received, the next step is to cut them into the required dimensions. Using precision cutting machine, the steel pieces are shaped according to the design specifications. This is a critical step to ensure that all parts fit together properly in the final assembly.

After cutting, some parts of the rack, particularly the arms, need to be bent into the correct angles. Bending machines apply force to the metal to achieve the desired shape, ensuring the arms of the cantilever rack can extend outward to support the stored items.

Punching is a step where holes are created in the metal for bolts, screws, or rivets. These holes are essential for connecting different components of the cantilever rack and ensuring the assembly is stable and secure.

Shaping involves further refining the form of the parts. This step may include additional adjustments, such as rounding off edges or fine-tuning the curves of the rack’s arms, ensuring both strength and safety for use in industrial storage.

Polishing is done to smooth out any rough edges or surfaces left after cutting, bending, and shaping. It helps improve the appearance of the rack and also ensures that the surfaces are safe to handle, without any sharp edges that could cause injury.

Welding is the process where the various components of the cantilever rack are joined together. The arms, columns, and base are welded to form a solid, cohesive structure. The welding must be precise to ensure the cantilever rack can withstand heavy loads and offer long-lasting performance.

Acid pickling is a cleaning process where the rack components are dipped into an acidic solution. This step removes any scale, rust, or impurities from the steel, ensuring that the metal is clean and ready for the next step of coating.

Once the rack components have been cleaned, our cantilever racking all treated by smooth powder-coating paint. This helps prevent rust and corrosion, ensuring the racks are durable in harsh environments. The paint also gives the rack a finished, polished appearance. Different colors and finishes can be applied based on customer preferences and the intended use of the racks.

After painting, the cantilever racks undergo a final inspection to ensure they meet quality and safety standards. Once approved, the racks are packaged and shipped to clients, ready to be installed in warehouses or storage facilities.

The right type of cantilever rack can optimize storage, reduce space wastage, and improve workflow in your warehouse. Whether you need to store light-duty items or heavy, industrial goods, understanding the various types of cantilever racks is essential for ensuring that your storage solution meets your needs efficiently.

Single-sided cantilever racks are ideal for situations where products need to be accessed from only one side. These racks typically feature a vertical post with extending arms on one side, allowing for the storage of long or bulky items.

These racks are commonly used in warehouses or retail settings where products like pipes, lumber, or steel bars need to be easily accessed from one direction. Ideal for applications where space is limited on one side or where loading and unloading occur from a single aisle.

Pros:

Space-efficient, especially in narrow aisles.

Simple design for easy installation and use.

Offers a clean, open structure for easy product access.

Cons:

Limited accessibility if items need to be accessed from both sides.

Less flexible compared to double-sided options.

Double-sided cantilever racks offer storage on both sides of the vertical support, providing double the storage capacity in the same footprint. These racks are often used in environments with high traffic, allowing for simultaneous loading and unloading from both sides.

Double-sided racks are ideal for large warehouses or distribution centers where high storage capacity and quick access are necessary. They are often used to store materials like timber, furniture, or metal products.

Pros:

Increased storage capacity within the same footprint.

Faster inventory retrieval from either side of the rack.

Ideal for high-demand environments.

Cons:

Requires more aisle space for accessibility.

Can be more complex and costly to install.

Structural cantilever racks are built for heavy-duty applications and can withstand large loads. Made from high-strength steel and heavy-duty components, these racks are designed to store bulky, large items like steel beams, coils, and heavy machinery components.

These racks are typically found in industries such as construction, manufacturing, and steel production, where heavy materials need to be stored safely and efficiently. They are excellent for warehouses dealing with industrial-grade materials.

Pros:

Built for heavy-duty storage needs.

Can hold large and bulky items.

Extremely durable and robust.

Cons:

Heavier and more expensive than lighter-duty racks.

Requires more installation time and effort.

Roll-formed cantilever racks are made from lightweight steel that’s shaped into a specific profile for strength and durability. These racks are more affordable than structural racks, and their components are easy to assemble and adjust.

Roll-formed cantilever racks are great for storing medium-weight materials, like smaller timber, plastic piping, or furniture. They are commonly used in industries that require an adaptable, cost-effective solution for storing products of varying sizes.

Pros:

More affordable compared to structural racks.

Lighter and easier to install.

Adjustable design for flexible storage needs.

Cons:

Less durable than structural racks for heavy loads.

May not be suitable for extremely large or heavy materials.

A cantilever mezzanine is a two-tiered rack system that utilizes the overhead space to create additional storage capacity. It’s essentially a platform or second floor built above existing cantilever racks, creating a multi-level storage solution.

Cantilever mezzanines are used in large facilities where maximizing vertical space is critical. They are often employed in warehouses, distribution centers, and industrial plants that require substantial storage space for goods that are not necessarily accessed frequently.

Pros:

Maximizes vertical space and provides additional storage levels.

Ideal for businesses with high storage demands.

Can be customized to fit specific warehouse layouts.

Cons:

Requires additional structural support and investment.

More complex installation compared to single or double-sided racks.

Cantilever racks and cantilever mezzanines are both storage solutions used in warehouses, but they serve different purposes and have distinct characteristics. Here's a breakdown of their differences:

Purpose: Cantilever racks are designed specifically for storing long, bulky, or awkwardly shaped items such as pipes, lumber, and metal sheets. They allow for easy access to these items without the obstruction of vertical columns.

Structure: A cantilever rack consists of vertical uprights that support horizontal arms. These arms extend outward, providing a clear space for loading and unloading goods. The racks can be configured as single-sided or double-sided, depending on the storage needs.

Flexibility: The arms are adjustable in height to accommodate various lengths of stored items. This modularity allows for efficient use of vertical space and easy reconfiguration as storage needs change.

Accessibility: Cantilever racks facilitate direct access to each load unit without needing to move other products, making them ideal for high-density storage of long items

Purpose: A cantilever mezzanine is a raised platform supported by cantilever racks, designed to create additional floor space within a warehouse. It effectively utilizes vertical space by allowing storage or work areas above existing storage systems.

Structure: The mezzanine is built using cantilever rack components that provide the necessary support for the platform. This structure allows for the creation of multi-level storage solutions or workspaces without extensive construction.

Functionality: Cantilever mezzanines can serve multiple purposes, including additional storage capacity, workstations, or picking zones. They can hold various types of loads and help maximize the overall efficiency of warehouse operations

Space Utilization: By adding a mezzanine level, warehouses can significantly increase their usable space without expanding their footprint. This is particularly beneficial in facilities with height restrictions

| Feature | Cantilever Rack | Cantilever Mezzanine |

|---|---|---|

| Primary Function | Storage for long/bulky items | Additional floor space for storage/work areas |

| Structure | Vertical uprights with horizontal arms | Raised platform supported by cantilever racks |

| Flexibility | Adjustable arms for various item lengths | Multi-level design allows for diverse uses |

| Accessibility | Direct access to stored items | Access via stairs or lifts; may require more planning |

| Space Utilization | Efficient use of floor space | Maximizes vertical space without expanding footprint |

Cantilever racks are incredibly efficient for inventory management. They allow items to be stored without the need for bins or crates, which makes it easier to access and organize products. With an open design, the inventory is visible at all times, improving stock management.

One of the standout features of cantilever racks is their flexibility in size. Racks can be customized to fit specific warehouse dimensions and material types. Whether you need a rack to store small pipes or oversized furniture, there’s a cantilever rack design for every need.

Load-bearing capacity is a critical factor when selecting a cantilever rack. Depending on the materials you intend to store, you’ll need racks that can handle heavy-duty items. Cantilever racks can be designed to bear substantial loads, often ranging from 1,000 to 10,000 pounds per arm, depending on the design.

The price of a cantilever rack can vary based on size, customization, and the load-bearing capacity. Generally, the cost is higher than that of standard shelving systems due to the materials and manufacturing processes involved. However, their efficiency in storage often justifies the investment in the long run.

Construction

Storing Lumber and Building Materials

In the construction industry, storage space is often limited, but the need for organized storage of long materials like timber, planks, and drywall is crucial. Cantilever racks are perfect for this, as they provide a sturdy and organized place to store and access lumber quickly.

Handling Steel Pipes and Beams

For larger construction projects, steel beams and pipes are common materials that need to be stored efficiently. Cantilever racks provide excellent support for these heavy items, keeping them organized and easily accessible.

Manufacturing and Distribution

Organizing Long Components and Parts

Manufacturers that deal with long components, such as metal rods, bars, and pipes, need efficient storage systems. Cantilever racks make it easy to store and organize these items, helping streamline production and minimize downtime spent searching for materials.

Streamlining Assembly Line Storage

In industries where assembly lines are key, cantilever racks allow for quick and easy access to parts and components. This reduces downtime during the manufacturing process and ensures that workers can get the parts they need without delay.

Warehouse and Retail Storage

Maximizing Vertical Space in Warehouses

For warehouses looking to maximize storage, cantilever racks offer a solution that doesn’t compromise accessibility. The open structure of cantilever racks enables better vertical storage, allowing businesses to make use of all available space while providing easy access to goods.

Displaying Large or Bulky Retail Products

Retail businesses that deal with large or bulky items such as furniture, mattresses, or building supplies can benefit from cantilever racks. The open arms allow for easy visibility and access, making it easier for customers to view and select items.

Automotive Industry

Storing Auto Parts and Components

Cantilever racks are commonly used in the automotive industry to store auto parts such as exhaust pipes, fenders, and bumpers. The ability to store these long, irregularly shaped items vertically keeps the workspace organized and safe.

Custom Storage Solutions for Heavy Parts

Heavy auto parts, like engines and transmissions, require a secure storage solution. Cantilever racks can be customized with reinforced arms and supports to handle the weight of these heavy components.

Pipe Storage

Organizing PVC, Steel, and Copper Pipes

Cantilever racks are perfect for organizing various types of pipes, including PVC, copper, and steel. These materials are often used in plumbing, construction, and other industries, and cantilever racks keep them neatly arranged and easily accessible.

Storing Pipes for Easy Access and Distribution

In industries where pipe distribution is a key part of the workflow, cantilever racks allow for quick access. Whether you're storing them in the warehouse or at a distribution center, these racks ensure that materials are kept organized and easy to retrieve.

Furniture and Home Goods Stores

Displaying Furniture and Large Items

For furniture retailers, cantilever racks offer a way to display large, bulky products like couches, tables, and cabinets. The open design allows for easy visibility and access to items, helping customers browse efficiently.

Efficient Use of Floor Space

Cantilever racks enable furniture stores to maximize their floor space by storing items vertically. This is particularly useful in smaller stores where floor space is limited.

Outdoor and Yard Storage

In industries that require outdoor storage, such as landscaping or construction, cantilever racks provide a way to organize materials like bricks, stones, and timber. These racks are often built from weather-resistant materials to ensure durability in harsh environments.

Heda Shelves offers a range of custom solutions tailored to your specific storage needs. Whether you need bespoke dimensions or specialized arm designs, they can provide the perfect rack for your warehouse.

With 20+ years of experience, Heda Shelves has built a reputation for providing high-quality storage systems. More than 5000+ warehouse choose our tailor racking solution.

Heda Shelves ensures timely delivery, making sure your racks are available when you need them. This commitment to speed can be crucial for businesses that rely on swift turnaround times.

Heda Shelves offers competitive pricing, making them a cost-effective choice for businesses looking to optimize their storage without a high cost in moving your warehouse.

With a global presence, Heda Shelves brings expertise to warehouses around the world, understanding different market demands and providing solutions that cater to a wide range of industries.

Cantilever racks are an essential part of warehouse optimization, offering space-saving, flexibility, and efficient storage for long or heavy items. Whether you’re managing a construction site or organizing a retail warehouse, these racks can help streamline your inventory system.

Whether you’re looking for the affordability and reliability of warehouse storage solutions and special shape inventory storage, here’s a rich experience cantilever racking expert service for you. At Heda Shelves, we’re here to help you find it. Contact us today for customized solutions that will bring your high-efficiency storage solution.

1.What are cantilever racks used for?

Cantilever racks are used to store long, bulky items such as pipes, lumber, or furniture, which don't fit well on traditional shelving.

2. Can cantilever racks be customized?

Yes, cantilever racks can be fully customized to fit specific sizes, load requirements, and materials.

3. How much weight can a cantilever rack hold?

The load capacity varies, but typical cantilever racks can hold between 1,000 to 10,000 pounds per arm.

4. Are cantilever racks expensive?

While they are typically more expensive than traditional shelving, their efficiency and space-saving benefits often make them a worthwhile investment.

5. How do I choose the right cantilever rack for my warehouse?

Consider the size of the items you need to store, the weight they will bear, and the available space in your warehouse when choosing a cantilever rack.

Hi! Click one of our members below to chat on