A Industrial Racks is designed to hold substantial weight, making it ideal for storing large, bulky items.

These racks are made of Q235 Cold Roller Steel and finish by Acid Washing&Phosphating of industrial use, ensuring that your goods are stored securely and safely. Our industrial widely apply to logistic warehouse,cold storage warehouse, retail or trade distributor centers.

Material :

Q235 Cold Roller SteelLoad Capacity :

1000-5000KG Per LayerColor :

Blue&OrangeSurface Treatment :

Acid Washing&PhosphatingRelevant Certificate :

CE/ISOLayers :

CustomOEM/ODM :

AcceptedProduct Parameter

|

Product Name |

heavy duty commercial shelving |

|

Material |

Cold-rolled Steel |

|

Product size |

Length: 2300 / 2500 / 2700 / 3000 / 3300 / 3600 / 3900mm Width: 900 / 1000 / 1100 / 1200mm Height: 2000-6500mm |

|

Thickness |

column:1.5mm, 2.0mm |

|

Load capacity |

800-5000 kg per layer |

|

Layers |

2-5 adjustable layers (can be custom made) |

|

Color |

RAL color; As per customer's requirement |

|

Surface |

Electrostatic spray surface |

|

Feature |

Anti-rust, Corrosion-protection |

|

Guarantee period |

5 years warranty |

|

Remark |

OEM&ODM accepted |

|

Relevant Certificate |

CE |

|

Use area |

Warehouse, factory, storage place |

|

Structure |

Knock down structure, easy assembling, convenient for delivery |

|

Function |

storage goods, rack, storage |

|

Product range |

warehouse, storage place |

Product Detail:

Features:

Optimum Space Utilization at Factory Prices

Our industrial warehouse racking systems are engineered for maximum space efficiency without compromising quality. With a comprehensive range of sizes, colors, and configurations, our racking solutions are not only easy to assemble and dismantle but also adjustable to meet your specific storage needs. Experience high-quality products at competitive factory prices.

Infinite Adjustability and Versatile Options

Designed with flexibility in mind, our racking systems are infinitely adjustable, allowing you to customize your setup effortlessly. Choose from a wide array of options and components to create the perfect storage solution tailored to your operational requirements.

Maximized Space Use with Optimal Accessibility

Our racking systems are designed to maximize space utilization in any warehouse configuration while ensuring that product accessibility remains a top priority. Enjoy efficient organization and easy retrieval of goods, enhancing your overall operational efficiency.

Strength and Rigidity for Damage Prevention

Constructed with robust materials ,Q235 Cold Roller Steel with Acid Washing&Phosphating. Our racking solutions provide exceptional strength and rigidity, effectively preventing compression damage to stored goods. This durability ensures that your inventory remains safe and intact, reducing the risk of loss or damage.

Versatile Applications Across Industries

Our industrial racking systems are widely applicable across various industries, including libraries, archive rooms, markets, grocery stores, and warehouses. No matter your sector, our solutions can be adapted to meet diverse storage needs, making them an ideal choice for any environment.

Main Components

Frames

The frames are the backbone of our racking systems and consist of two uprights, horizontal and diagonal brackets, base plates and accessories.

Uprights: slotted every 50mm to facilitate crossbar installation. The depth of the frame is determined by the pallet size, with a 1,100mm frame typically used for 1,200mm deep Euro pallets.

Uprights

Upright heights and column thickness are customizable, which affects load-bearing capacity. Other details include:

Brackets: horizontal and diagonal brackets are removable for easy transport.

Hole customization: options include diamond and trapezoidal holes.

Common Specifications:

Upright Dimensions: 90 x 70 x 1.2mm, 108 x 85 x 1.2mm

Height: Regular upright heights range from 5 to 12 meters; taller racks can be customized with thicker upright supports.

Crossbars (Inner Length Dimension)

Crossbars are horizontal components that carry the load. They are connected to the uprights via connectors or couplers that slot into slots. Key features include:

Connection system: Hooks on the connectors secure the main rack structure at both ends, enhancing load capacity and preventing deformation due to weak connections.

Material: Heavy duty racks are usually made of box beams, which consist of two iron sheets welded together, with thickness options of 1.0mm, 1.2mm, 1.5mm and 1.8mm.

Stress distribution: The center of the box beam is a concave structure, which improves stress management.

Specifications:

Dimensions:

Length limit: Generally, the length of the beam should not exceed 3 meters due to reduced load-bearing efficiency; for layers longer than 3 meters, the load per layer should not exceed 800 kg.

Bottom plate

Bottom plates vary depending on the required load and the upright model used. Each slab is secured to the floor with one or two anchor bolts.

Interlocking beam sections

Our interlocking beam sections are available in lengths up to 4.5 metres and have a maximum load capacity of 5,000 kg per tier. For other specifications please contact us directly.

Accessories

For enhanced functionality and safety, we offer a wide range of accessories including:

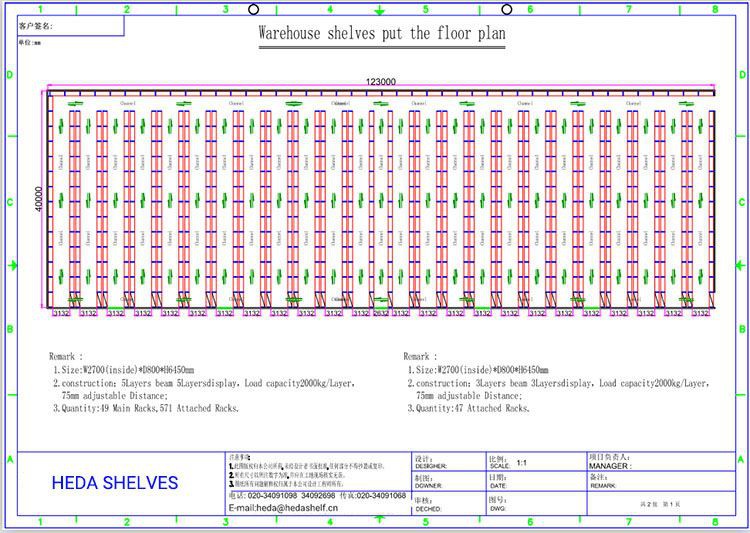

How to get a floor plan for your warehouse?

1. Send the information of your pallet with goods including length, width, height and weight.

Or let us know size and loading capacity for the racks your need.

2. Send a layout of your warehouse.

And you can get complete design for your warehouse.

Successful Cases

Our Company's market cover 100+ countries, with 5000+ project experience. heda shelf supply one-stop solutions and free layout design. We have many successful case, such as Multi-level Mezzanine system in Thailand, 1000 Sqm New Mezzanine Floor Project With Lift, Multi-level Mezzanine In UAE Is Installing and so on, learn more, pls contact heda shelves.

Why would everyone choose us:

1.We have a wide range of product category for you to choose,from related products to fashion design.

2.We have bureau veritas certification and EC Declaration of conformity.

3.We use thick steel and guarantee high coating quality.

4.We provide installation drawings and video instruction for free.

5.Annual production capacity:15000 sets of shelves

6.Since 2001,Factory + trade,factory more than 13000m²;office area 500m² in pazhou,near guangzhou international convention center.

7.We offer OEM/ODM service with our own strong innovation ability.

Company Information

HEDA Shelves Co., Ltd was founded in 2001. We specialize in designing, manufacturing, selling and installing all types of warehouse racks, storage shelves and tool display racks, etc.

Up till now, our factory has workshops occupying a floor area of more than 13000 square meters and 150 workers. Heda own powerful technical strength, advanced manufacturing equipment. Such as Tube cutting saw, Tube punching machine, Guillotine shear machine, Punching machine, Plate bending machine, Spot welding machine. Our scientific design, delicate workmanship, satisfactory quality and reasonable price make our corporate image perfect.

We Attend Canton Fair from 2012 to 2019, each year 2 times. Also,We Attend other famous exhibitions, such as Expo Ferretera, PROMAT, Material Handling Middle East and so on.

Contact us:

Mobile:+8618124246657

E-mail:abby@hedashelf.cn

Hi! Click one of our members below to chat on