Product description:

| Type : | Mezzanine Racking |

| Load Capacity : | 500-5000kg/layer (or customized) |

| Material : | High-grade Q235 Cold Rolled Steel |

| Color : | Customized |

| OEM/ODM : | Accepted |

| MOQ : | 10 sets |

| Supply Ability : | 5000 sets per month |

| Treatment : | With electrostatic spraying and acid phosphating treatment, is solid in construction and anti -rust in appearance. |

| Packaging Details : | Packed by cartons with air bubble foam |

| Delivery Time : | 10-15 work day upon receipt of the deposit |

| Payment Terms : | 30% deposit upon signing the contract, the balance will be cleared by T/T before delivery. |

Features:

1.Walkway surface can be customized to be many types of floorings.

2.Totally assembly structure,no need cutting and welding.

3.A very quick and cost effective way to create new space

4.Can be built over existing equipment and work areas

5. The characteristic of corrosion-protection could keep the shelves well.

Mezzanine floor platform Advantage:

All composite racking structure,patented light steel floor panel structure,locked by another patented parts which leads to an integrated,smooth floor panel with high load capacity,low cost,quick construction.it can be designed into one layer or multi layers according to actual situation,full use of the space can be ensured.it is widely used in the areas of automobiles,electronics,mechanics and etc.

Company Information:

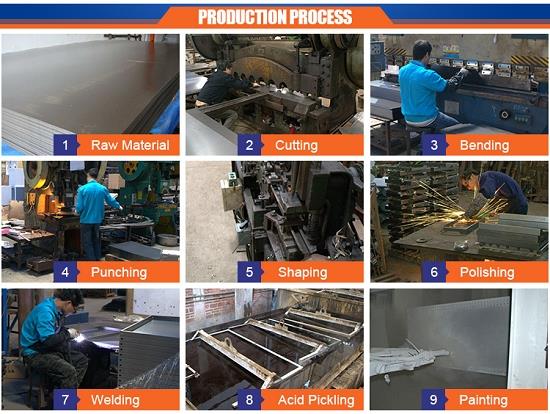

Production Process

Material Preparation:Carefully selected the material, get well preparation for the next craftsmanship;

Cutting Material: Based on the size and design of products, to cut down each parts of the shelves

Bending steel: According to the workmanship of shelves, to bend the steel for purpose of matching the racks

Punching: Through punching machine, to perforate holes to each corner of steel board, this step allow each rack to combine with each other

Rolling: Processing the rolling machine then shape the steel to finish one basic racks construction

Polishing: This polishing machinery is mainly to wash out the ray abrasive damage layer and make the surface bright as one mirror.

Welding: Making welds for joints of racks and further finish the racks components

Acid Washing and Phosphating: This workmanship is aim to prevent the corrosion of steel to some extent, and function of protecting the basic body of racks. In another aspect, laying the foundation before coating could improve the adhesion and corrosion resistance of paint film and in the cold metal processing, to reduce friction lubrication.

Spray Painting and Drying: Professional spray painting machine evenly like to put on one new colorful clothes for steel board, the color could be optional then drying the steel board.

Product Packing:

Generally, shelves are flat packed by air bubble film/ film in standard export cartons. Other packing like wooden box are available to clients’ requirement.

Custom plywood crate or box for heavy sheet metal parts.

Heavy duty carton for small and lighter metal parts.

Bubble bag or protective film for inner protection to avoid scratches.

Plywood pallet is available when sheet metal products are in large amount.

Shipping marks as per request.

FAQ:

1. Q: Could you produce according to customers’ design?

A: Sure, we have very rich experience in customizing shelves.

2. Q: Can you customized style, size, colors?

A: Yes, we have rich experience more than 10 years in customization.

3. Q: Where is your factory? Can I visit ?

A: Our factory is located in Foshan, Guangdong. You are warmly welcome to visit whenever you are available.

4.Q: Are you factory or trading company?

A: We are a factory specialized in all kinds of supermarket shelves, warehouse racks and different,kinds of display stands. We have over 10 years of experience in field.

5.Q: May I know the status of my order?

A:Yes .We will send you information and photos at different production stage of your order. You will get the latest information in time.

Hi! Click one of our members below to chat on