About Us

Guangzhou Heda Shelves Co., Ltd

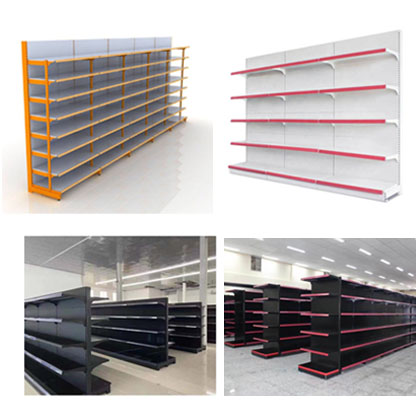

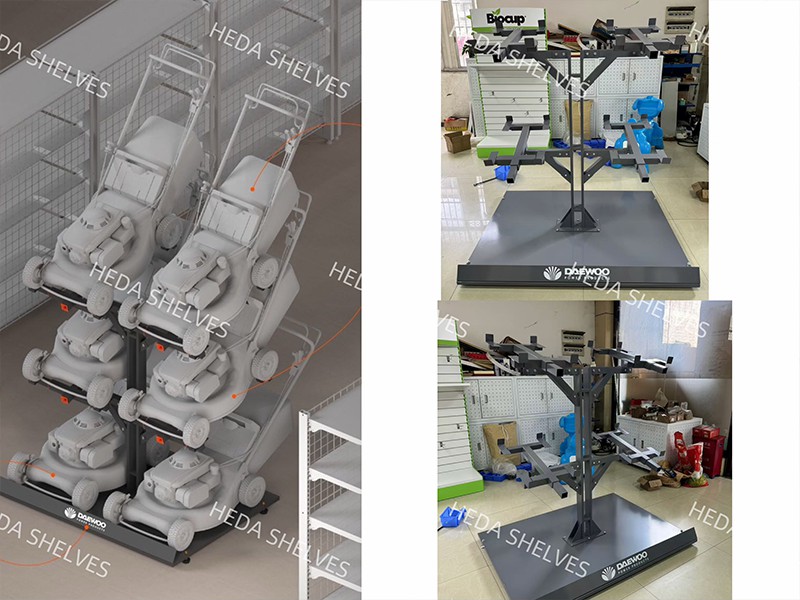

Guangzhou HEDA Shelves Co., Ltd., established in 2001, is a professional company specializing in designing, manufacturing, selling and installing all types of storage racks, display shelves, and all types of supermarket equipment. HEDA Shelves is located in Pazhou -the Exhibition Base of the Chinese Import and Export Fair Complex. We participate in many exhibitions every year, such as Canton Fair, TILOG - LOGISTIX 2018, etc.

We have made various fashionable shelves for different well-known brand customers. Our products are very popular in Southeast Asia, Japan, America, Canada, Australia and Europe.